In 3D printing, when a resin is placed into a printer, the product that is produced is the green-state form. The green-state means that the product is not yet fully cured because the laser projectors that form the part do not have enough time or energy to do so. Therefore, after printing, it is essential that the 3D printed part is washed with isopropyl alcohol to prevent the residual uncured layer of resin on the material from being cured to the part and filling in the fine details that may be important to the part’s function. After being washed with isopropyl alcohol, the material is cured under either a UV broadband or LED light source. Post-curing is important in 3D printing because it finishes the cure that the printer started.

Curing Systems

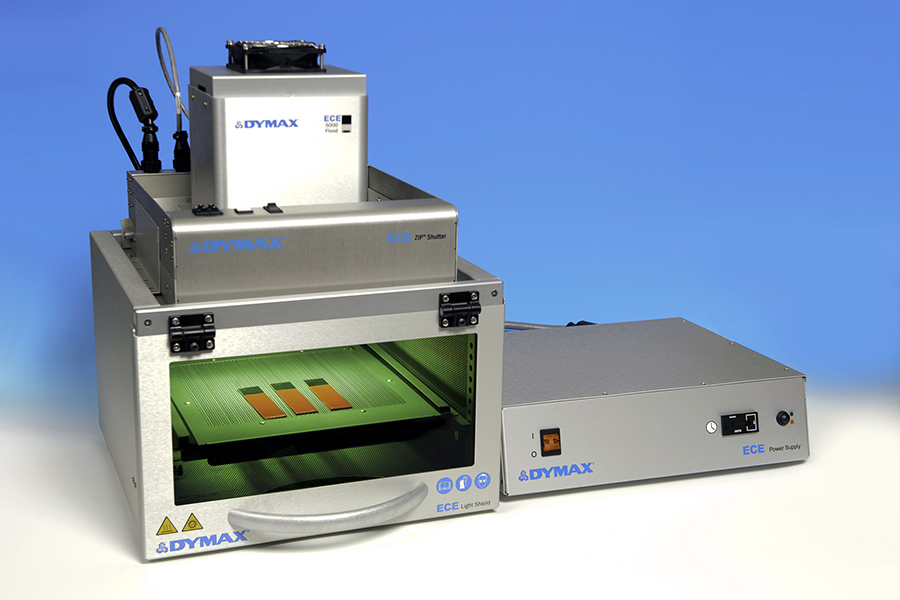

UV flood-lamp light-curing systems are designed for area curing of multiple assemblies at once. Typical flood-lamp curing systems are composed of three main components: a UV flood lamp, manual or automatic shutter, and a light shield. Regarding 3D printing, this means that the entire printed material can be placed under the lamp, typically for 2 minutes, and the entirety of it will be fully cured. This form of post-cure ensures that the printed material is representing its true physical properties.

Rework & Repairs

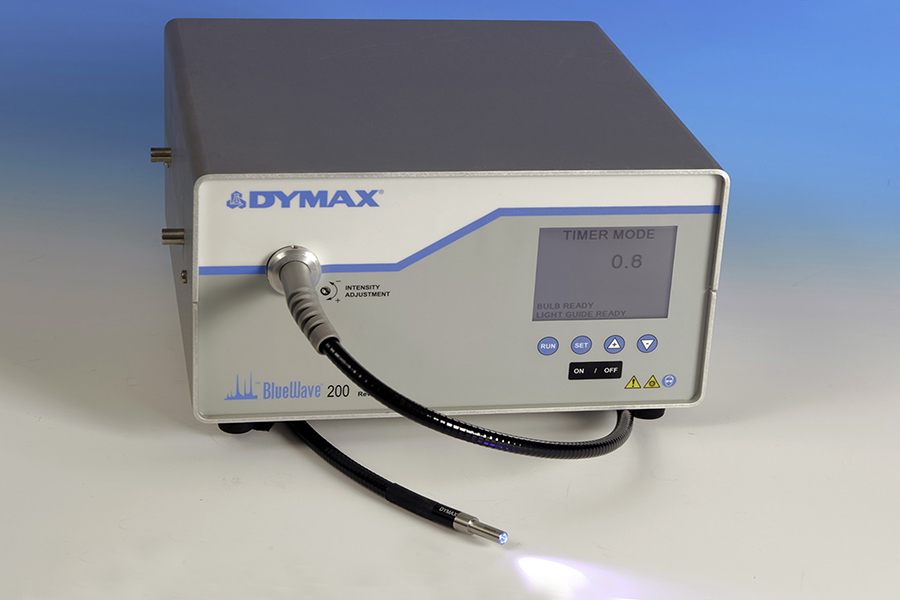

UV spot-lamp light-curing systems are ideal for rework or repairs, such as curing drain hole fills, assembling larger models, or repairing cracked or broken models. A spot-cure system generates its cure energy from high-intensity UV LEDs or broadband bulbs. A spot lamp that utilizes LEDs does not generate a lot of heat, so it is ideal for curing thermally sensitive materials and will not cause distortion in a printed material. This method of curing is useful for repairing or assembling small, detailed 3D printed parts or for assembling a larger part from multiple small prints.

Spot lamps cure a material quickly and efficiently allowing for better process control. Both flood-lamp and spot lamp curing equipment can help a formulator prepare their 3D-printed material for testing, as well as add final touches or repairs to a final 3D-printed product.

Would you like to learn more about Bomar® Oligomers for 3D printing?